When selecting power sources for welding, take into account technological and economic indicators. The choice of sources will ultimately be based on economic calculations, but this economic calculation will be performed from the set of sources that satisfy the first two criteria. Therefore, it is necessary to know about these two criteria.

The power source is considered to be technological if it provides:

- the arc stability (estimated by the coefficient of stability– КУ);

- the arc elasticity;

- the minimum level of spattering of the electrode metal.

The arc elasticity is the ability of a stable arc to burn without breaks in its elongation.

The criterion of elasticity of the arc is the maximum length of the arc, fixed at the time of the break at its elongation. This property of the arc is very important, and it is provided by the properties (parameters) of the power source. It is necessary that in case of burning when there are random deviations of arc length, the arc does not stop.

To increase the elasticity of the arc is possible by increasing the idling voltage of the source, by introducing into the composition of the coating of the electrodes and fluxes elements with low ionization potential (for example, sodium, potassium, calcium). In addition, the elasticity of the arc increases with increasing welding current. Thus, the elasticity of the arc is determined by the properties of the power source.

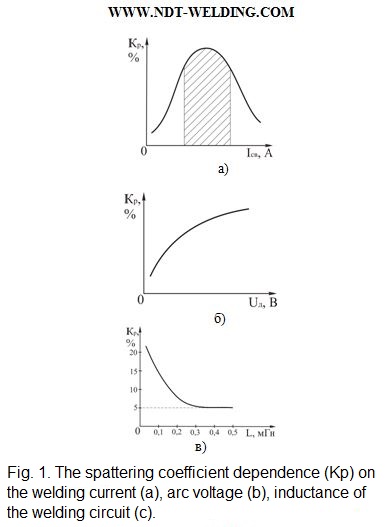

In manual arc welding with coated electrodes, and especially when welding in CO2 (semiautomatic and automatic), the significant spattering of the electrode metal is observed, which is taken into account by the spattering coefficient – КР [%]. To reduce the spattering coefficient by choosing the rational parameters of the welding regime (IСВ,UД), as well as the value of the inductance of the welding circuit (L, Гн).

When welding in CO2, there is a zone of welding currents (Fig. 1, a), in which a considerable spattering of the electrode metal is observed (up to 20 … 25%). As the arc voltage (Uд) increases, the КР coefficient also increases (Fig. 1, b). Thus, welding is best performed with a short arc. As the inductance of the welding circuit (L) increases, the КР coefficient decreases (Fig. 1, c). Usually, the values of inducibility L = 0.25 … 0.4 mH are optimal (further increase in L is useless). To this end, all welding rectifiers have in their composition smoothing chokes (SC), which are a device providing a given level of inductance (L).

To the technical and economic indicators, power sources include:

- cos φ;

- the efficiency – η;

- the coefficient of full power use– С; С= cos φ× η.

When choosing power sources, it is necessary to focus on those whose marked indicators are maximal.

In addition, it must be taken into account that these figures (for the same source) increase with increasing loading to nominal values.

The operation of power sources modes include the following:

– the relative load duration– ПН [%] of the intermittent mode;;

– the duration of switching on – ПВ [%] for the re-short-time load mode.