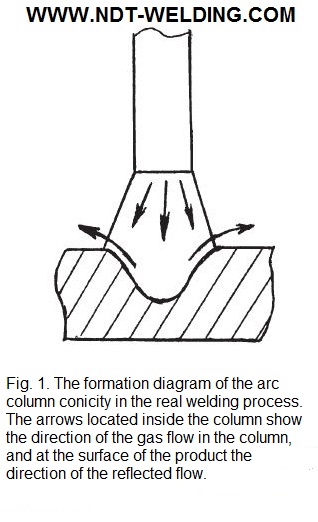

In the actual welding case, when the product under the arc is melted, the crater is formed, the walls of which direct the reflected gas flow not at an angle of 90° to the electrode axis, but under much smaller (see Fig.1).

The angle between the outer surface of the column and the direction of the reflected flow (its outer surface on the side of the arc column) also decreases, which leads to the even wider expansion of the arc column at the surface of the product.

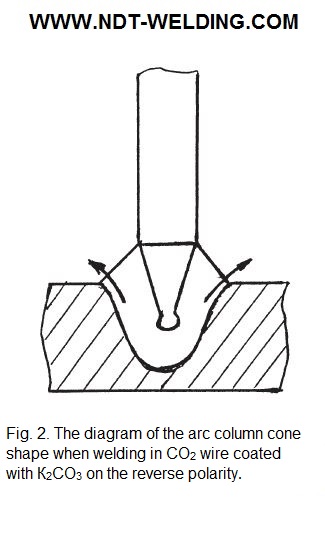

If the reasoning is true, then the shorter the column, the closer end of the electrode will be to the surface of the product and the greater the intensity of the reflected flux, the greater the angle will be at the upper base of the cone (arc column). This conclusion is confirmed experimentally. When welding with the Св-08Г2С wire with a carbon dioxide coating in an amount of ~ 0.01% of the mass of the wire during jet transfer in the reverse polarity in CO2, the outer part of the arc (Lвн) (see Fig. 2) is located between the electrode and the surface of the product and equal to about 1 … 2 mm, has the angle of cone expansion equal to ~120°.

Especially, in this case (with the jet transfer) that the intense gas flow is observed in the arc column, which naturally causes the intense, reflected flow. In addition, the gas braking at the surface of the plate or weld pool leads to the increase in the temperature of the reflected flow, and the gas temperature at the surface of the plate or the crater of the weld pool will be the greater, the more the gas flow velocity in the arc column, and this means that the temperature of the gas in the reflected stream will also increase in this case.

Since the velocity of the gas flow in the arc column during the jet transfer is much larger than in the case of the aspheric transfer, the temperature of the reflected gas flow in this case will be much larger, which contributes to the considerable conicity of the arc in this case.

The expanding the pole at the surface of the product when welding on the reverse polarity indicates that the dimensions of the cathode spot on the product can be determined by the transverse dimension of the arc column at the product surface. In this case, the significant decrease in the current density in the cathode spot and, consequently, the decrease in the intensity of the ionization process in the ionization part of the cathode region in this case is compensated by the significant increase in the gas temperature at the cathode surface at the cathode spot location, in the cathode area.