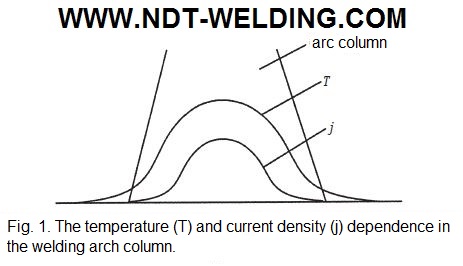

Usually, the current density distribution, temperature in the arch column is considered whether it is burning between the not melting electrodes or between the melting electrodes. At the same time, it is considered that the current density and temperature in the arch column are distributed as shown on Fig. 1.

However, when welding by the melting drop electrode, passing through the arc interval, have to make essential changes to this distribution as their sizes are commensurable with arch column sizes at the real modes of welding. Let’s consider it in more detail. Regardless of the arc column intersects one or more droplets, the current density therein must be much less than in the arc column, since otherwise the top and bottom surfaces of both one and several drops would have formed the cathode and anode active spots, it is impossible, as shown by the following reasoning.

Let’s consider this question on the example of the arch burning between steel electrodes in carbon dioxide. The total falling of the cathode and anode tension for these arches makes (17 … 19) V, and the potential gradient is equal in these arc column to Uд/ℓд ≈ 2,5 ・ 103 V/m, where Uд — the power failure in the arch column, V; ℓд — the arc length, m. Therefore for a drop diameter of dк = (2…3) ・ 10-3 m the average power failure between its top and lower surfaces will make ΔUср ≈ (Uд/ℓд) ・ (dк/2) = (2,5…3,8) V, that there is much less total falling of cathode and anode tension. It demonstrates that on the drops front and back surfaces there are no cathode and anode spots which would exist on condition of passing of current through them with a density close to current density in the arch column. It, in turn, means that current density in the drop crossing the arch column is much less than density of current in the arch column.