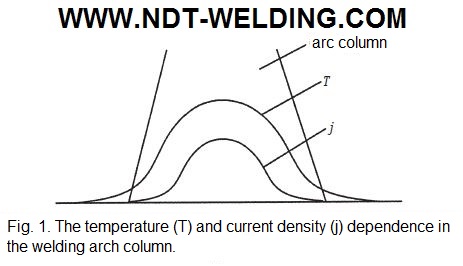

Usually, the current density distribution, temperature in the arch column is considered whether it is burning between the not melting electrodes or between the melting electrodes. At the same time, it is considered that the current density and temperature in the arch column are distributed as shown on Fig. 1.

However, when welding by the melting drop electrode, passing through the arc Continue reading →