The next type of defects monitoring, which we will consider, is based on the sample destruction of the welded joint with notches along the weld. This type of test is used mainly in the pipeline industry and is regulated by the American Petroleum Institute API 1104 standard. This method is based on the evaluation of faultlessness by breaking the sample over the weld and then monitoring the surface for the presence of discontinuities. The break is localized in the welding zone by means of notches on two or three surfaces. The typical sample for fracture testing is shown Continue reading →

The self-regulation mechanism of the arc column shape (Part 2).

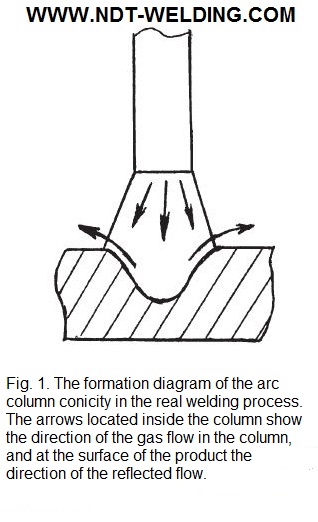

In the actual welding case, when the product under the arc is melted, the crater is formed, the walls of which direct the reflected gas flow not at an angle of 90° to the electrode axis, but under much smaller (see Fig.1).

The angle between the outer surface of the column and the direction of the Continue reading →

The metal structure basis (Part 2).

As we mentioned earlier, at any given temperature, the metal atoms are at the strictly defined distance from each other. In other words, they carry in themselves a certain internal energy. Since the heat is one kind of energy, the internal energy of the metal increases with increasing temperature. This additional energy causes the increased amplitude of atomic vibrations, which in turn increases the interatomic distance. We can visually observe the effects of this additional energy, since as individual atoms move apart, the overall dimensions of the metal part increase. On the contrary, any decrease in the temperature of the metal leads to the fact that the atoms approach each other. In this case, the compression of the Continue reading →

The polymorphic transformations in alloys (Part 2).

The polymorphic transformation of the solid solution upon heating and cooling consists of the lattice rearrangement and diffusion redistribution of the components between the phases. It is usually called normal. The normal β → α recrystallization occurs as a result of disordered transitions of atoms across the interface and is accompanied by the redistribution of the atoms of the components, i.e., their diffusion over large distances. This is realized with the slow cooling.

In some cases, the accelerating cooling, β → α-recrystallization can be prevented Continue reading →

The non-existence of defects monitoring in the weld seams (Part 2).

The second type of the bending test equipment with a mandrel is a standard device in which hardened bearings on the matrix are replaced by rollers. This helps to reduce the frictional force acting on the specimen when bending, and allows you to perform bending with less effort. The last of the common devices for bending tests with a mandrel is called the wrapping device. It is named so because the sample is bent by winding it around the fixed mandrel.

In some qualification tests of low-carbon steels, it is required that the sample to be Continue reading →